Unified Communications technologies are capturing the attention of virtually every industry in today’s digitally-transforming landscape. Promising better collaboration, productivity, and efficiency among teams, these tools can help brands to achieve evolving corporate goals.

In sectors undergoing rapid evolution, like the manufacturing industry, UC can be particularly beneficial. Currently, the UCaaS market for manufacturing is growing at a CAGR of 14.47%, as Industry 4.0 pushes companies into a new age of work.

According to a 2022 industry outlook report by Deloitte, one of the major trends influencing manufacturing brands today is the growing demand for new digital technologies. As demands for more efficient and innovative product development evolve, tools like UC allow today’s organisations to operate at the highest possible levels.

What’s more, the right technologies can significantly reduce costs for budget-conscious brands. According to industry estimations, modernising outdated systems for communication reduces costs by around 30% on average while enhancing workflow.

Here’s your guide to the evolution of communication in the manufacturing sector.

The Rising Need for UC in Manufacturing

Manufacturing companies are currently in the midst of a rapid and crucial state of transformation. The landscape is growing more intelligent with the adoption of IoT, 5G, and Artificial Intelligence initiatives. At the same time, consumer demands are increasing, pushing businesses to explore new opportunities at an accelerated rate.

Unified Communications and other agile technologies are providing manufacturing brands with the tools they need to stay one step ahead of the competition and market changes. In particular, the UCaaS sector represents a significant opportunity to shift more everyday processes into the cloud, allowing for increased automation, workplace efficiency, and higher customer satisfaction.

Perhaps the biggest benefits of pushing manufacturing companies to shift toward UC include:

- Improved collaboration: Running a successful manufacturing company requires companies to empower their teams to collaborate and communicate in a seamless environment. Multiple specialists from different departments are often involved in safely and quickly bringing new products to market and completing projects. UC solutions connect all of the otherwise siloed areas of the manufacturing business to empower modern teams.

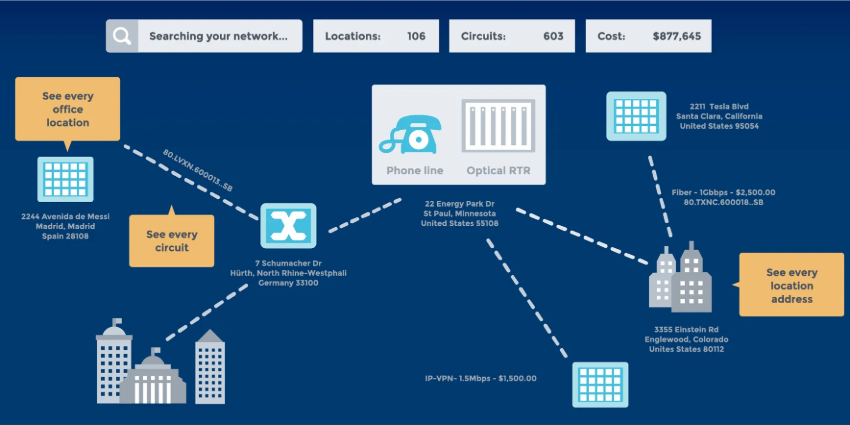

- Robust data management: UC solutions often act as more than just a communications centre. A cloud-based UCaaS solution can provide an all-in-one hub for connecting multiple sources of knowledge and data. Not only does this make it easier to track and improve employee productivity, but it can also assist with better asset and resource management in the manufacturing sector, keeping efficiency levels high.

- Improved quality assurance: UC solutions can allow more experts from around the world to be brought into environments they may not be able to access in person. Video conferencing tools and even XR solutions could allow quality assurance processes to be completed at a distance, allowing for faster time to market and reduced downtime. Teams can even access specialists from around the world to brainstorm solutions to problems.

- Reduced costs: As mentioned above, manufacturing teams are under excessive pressure to deliver exceptional results, with significant budgetary restraints. UC solutions can significantly reduce the costs associated with running a company. The right tools reduce the need for specialists to travel to various locations and ensure teams can communicate easily from different environments. UCaaS systems can even combine multiple crucial software tools in the same bill for better financial planning.

- Rapid innovation: The end-to-end connected nature of the UC environment makes it easier to collect valuable information about the performance of the business at scale. The right tools can help companies to collect the information they need to make better decisions about how to organise teams and resources and accelerate growth. Communications tools can even be connected with analytical reports from AI systems and IoT beacons.

The Trends Driving UC in Manufacturing

The manufacturing sector is perhaps one of the fastest-moving industries at the moment, as humanity continues to create and produce machinery at an incredible rate. By 2030 alone, the manufacturing space is set to reach a value of $1,370 billion, thanks in part to the rapid adoption of new technology.

While innovative new concepts like AI, IoT, and automation all present significant potential for this sector, truly sustainable evolution in any sector starts with solid communication and collaboration. To continue moving at a consistent momentum, brands need to first ensure they have the right communication tools in place.

Some of the most significant trends influencing the adoption of UC in manufacturing include:

- The rise of the cloud: Cloud technologies are having a massive influence on the speed with which manufacturing companies can create and innovate. Embracing UCaaS solutions allows manufacturing brands to operate at a faster pace, pulling insights from specialists all over the globe without the need for travel and complex scheduling. At the same time, it ensures every employee in the workplace remains on the same page, regardless of where they are, to reduce the risk of safety and security issues.

- AI and analytics: Artificial Intelligence stands as one of the most valuable pillars of Industry 4.0, helping companies to create machines that are more sustainable and effective. With AI and analytics built into the communication landscape, manufacturing brands can even implement predictive maintenance measures to keep issues to a minimum. An AI system can use reports submitted by employees over the years to detect when trends are emerging in the performance of a device or team, allowing for quick resolutions.

- XR and the Metaverse: XR and the metaverse are likely to play a significant part in the communication strategies of tomorrow’s manufacturing companies. XR solutions will allow teams to work together in more complex manufacturing environments, even when team members are distributed in locations all over the world. The metaverse could even create environments where users can build digital twins of products to test the functionality of certain machines and devices or analyse technology at a distance.

- Automation: In the manufacturing sector, automation has the power to improve team performance, accelerate innovation, and even reduce the risk of mistakes. Automated tools built into UC environments could even make employees safer by assisting with things like sending mass alerts to team members when danger is detected. The same automation tools can help with storing and collecting data which can later lead to better decision-making and more intelligent growth for the business.

The Rise of UC in Manufacturing

UC is one of the core technologies driving the future of the manufacturing industry. To unlock the potential of a smarter, more efficient and productive manufacturing floor, companies first need to start with better communication and collaboration between distributed teams.

As Industry 4.0 continues to evolve, unified communication platforms are likely to form the foundation of many digital transformation initiatives in the manufacturing space.